Focus: Triad region, at the center

The Triad, in the middle of the state, is also at the center of big business expansions.

—By Katherine Snow Smith and Kathy Blake

The hits just keep on coming for North Carolina’s Triad region. Toyota announced in mid-2023 that it is investing another $2.1 billion in its electric battery plant at the Greensboro-Randolph Megasite. This brings total expected investment in the car maker’s N.C. facility to $5.9 billion.

“Toyota believes in our world-class workforce to power its future success and I appreciate this enormous commitment here,” North Carolina Gov. Roy Cooper said at the time.

Toyota in 2021 revealed plans for $1.3 billion on an electric battery facility, then upped the investment by another $2.5 billion in 2022 before adding another $2.1 billion to the pot last year. It plans to employ 2,100 at the plant in Liberty outside High Point. Production is slated to begin in 2025.

Toyota said the Triad’s education system, diverse workforce, highway system with easy access to airports and seaports and collaboration between local and state government made it the right place to build big.

Rendering of Wolfspeed Silicon Carbide Materials manufacturing facility

The Triad is the center of the Carolina Core, which encompasses 17 counties displaying increasing collaboration. The Triad’s counties include Caswell, Rockingham, Stokes and Surry along the Virginia line; Forsyth and Guilford at the center, along with Alamance, Davie, Davidson, Montgomery, Randolph and Yadkin. The Carolina Core effort added five more counties: Chatham, Cumberland, Harnett, Lee and Moore.

The Carolina Core region includes 2 million workers and 7,100 acres of certified land to attract businesses. It is threaded together by a 120-mile stretch of U.S. 421 from Dunn to Yadkinville.

“We are the No. 1 state for business in the United States, and we are the heart of manufacturing in the state,” says Brent Christensen, president and CEO of the Greensboro Chamber of Commerce. “We have the best of what North Carolina has to offer without the headaches you might find elsewhere; we have the least traffic, the shortest commutes.”

Toyota’s huge investment shines an international spotlight on an area that already was known for its exceptional workforce, education and infrastructure.

“Our region is in play for a third of projects currently under consideration through the Economic Development Partnership of North Carolina,” says Mark Owens, president and CEO of Greater Winston-Salem. “Forsyth County has a robust pipeline of project interest both through local expansion and external relocation.”

The big announcements in the Carolina Core of 2021 and 2022 are now coming under construction or starting to hire. The projects involve jobs offering good wages and technological advances.

Boom Supersonic broke ground last year on its Overture factory at a 62-acre campus at the Piedmont Triad International Airport in Greensboro. It projects to hire up to 2,400 employees by 2032. Colorado-based Boom picked Greensboro to produce the Overture plane that will fly at twice the speed of today’s commercial jets. It has orders for 130 aircraft from American Airlines, United Airlines and Japan Airlines. Test flights are expected to begin 2026.

Energizer Holdings is investing $43 million to expand battery production and packaging at its Asheboro facility and plans to add 144 jobs. The company has been in the Asheboro community for almost 75 years.

Wolfspeed is investing $5 billion and bringing 1,802 jobs to Chatham County for its silicon carbide production site, which will provide semiconductor chips to power electric vehicles. It will be the world’s largest silicon carbide crystal growth facility.

VinFast, a Vietnamese electric car manufacturer, is investing $4 billion and plans to add 7,500 jobs in Chatham County. The company anticipates its plant will start production in 2025 and eventually produce 150,000 vehicles a year.

Siemens Mobility, a division of German engineering giant Siemens AG, plans to hire 506 workers for a passenger rail care manufacturing plant in Lexington. The Davidson County facility is slated to start operating next year.

Marshall USA a subsidiary of the United Kingdom’s largest privately owned aerospace and defense business, announced it is spending $50 million to establish a maintenance and engineering facility at the Piedmont Triad International Airport that will employ 240.

“North Carolina’s reputation for excellence in aerospace and military support continues to grow all around the world,” Cooper said when Marshall USA made its announcement. “Thanks to our state’s specialized workforce, companies like Marshall Aerospace that support the vital mission of our service members in uniform continue to choose North Carolina as the perfect place to do business.”

SITES ARE READY TO GO

The Carolina Core’s four certified megasites totaling 7,100 acres are luring more business.

The 1,800-acre Greensboro-Randolph Megasite that’s welcoming Toyota is minutes from I-40 and I-85. The Chatham-Siler City Advanced Manufacturing Megasite has 1,800 acres of shovel-ready land powered by excellent logistic and high capacity utilities. The 2,500-acre

Triangle Innovation Point, formerly Moncure Megasite,

in Chatham County is within 45 miles of three prominent research universities: UNC Chapel Hill, N.C. State University in Raleigh and Duke University in Durham.

And the Piedmont Triad International Airport ‘s 1,000-acre megasite that will be home to Boom Supersonic offers tenants runway access among other in-demand amenities.

ACADEMICS ADVANCE WORKFORCE

With more than 20 colleges and universities enrolling more than 100,000 students, the Carolina Core is exceptionally equipped to educate a talented workforce for its many varied employers. “I would stack our area up in talent produced by our colleges and universities with any in the country,” says Christensen.

Wake Forest University, UNC Greensboro, Elon University, High Point University and N.C A&T State University, along with several community colleges, play key roles.

The region’s community colleges customize training to individual needs of businesses in many industries, including advanced manufacturing, aviation and aerospace, automotive, biomedical and life sciences, technology, entrepreneurship, and logistics. An example partnership involves Wolfspeed and N.C. A&T State University, the leading U.S. producer of black engineers. Wolfspeed and N.C. A&T are planning a new research facility on the Greensboro campus.

“The R&D facility will enable the next generation of innovators to explore new processes, applications and breakthrough advancements to support the global transition from silicon to silicon carbide technology and achieve new levels of sustainability and energy efficiency across a variety of industries,” Wolfspeed CEO Gregg Lowe said in a release.

The R&D facility will be focused on silicon carbide to support the next generation of advanced compound semiconductors.

Similar collaboration is evident at Guilford Technical Community College, which works closely with Piedmont Triad International Airport in one of the Southeast’s biggest aviation programs, says President Dr. Anthony Clarke. “We do multiple classes every semester. So we are at about 420 to 440 students a year in aviation alone. There’s a constant demand for aircraft personnel.”

Also, the N.C. Federation for Advanced Manufacturing Education program created a partnership with GTCC to provide two-year, debt-free associate degrees in STEM fields connected with manufacturing.

The federation’s First in Flight chapter partners with Jowat Adhesives in Archdale, MasterBrand Cabinets in Lexington, Toyota Battery Manufacturing in Liberty and ZIEHL-ABEGG, a manufacturer of ventilation fans and drive technology for motors, in Greensboro.

“It’s an apprenticeship-type program in which students can earn a two-year degree in advanced manufacturing technology,” Clarke says. “You work for the company while you’re going through the program, then once you have your two-year degree you get hired by them and have a great career with all kinds of opportunities. They call it ‘world-class manufacturing,’ so they want to do best-in-the-world type training.”

INNOVATION WINSON-SALEM

Forsyth County and Winston-Salem’s Innovation Quarter is a hub for medical marvels, technology, research and entrepreneurs. Five academic institutions with 3,600 workers and 1,800 students operate in the IQ. It encompasses eight apartment complexes, including Piedmont Leaf Lofts, repurposed from two 1890s historic buildings, and Winston Factory Lofts, created from a 1920s industrial building.

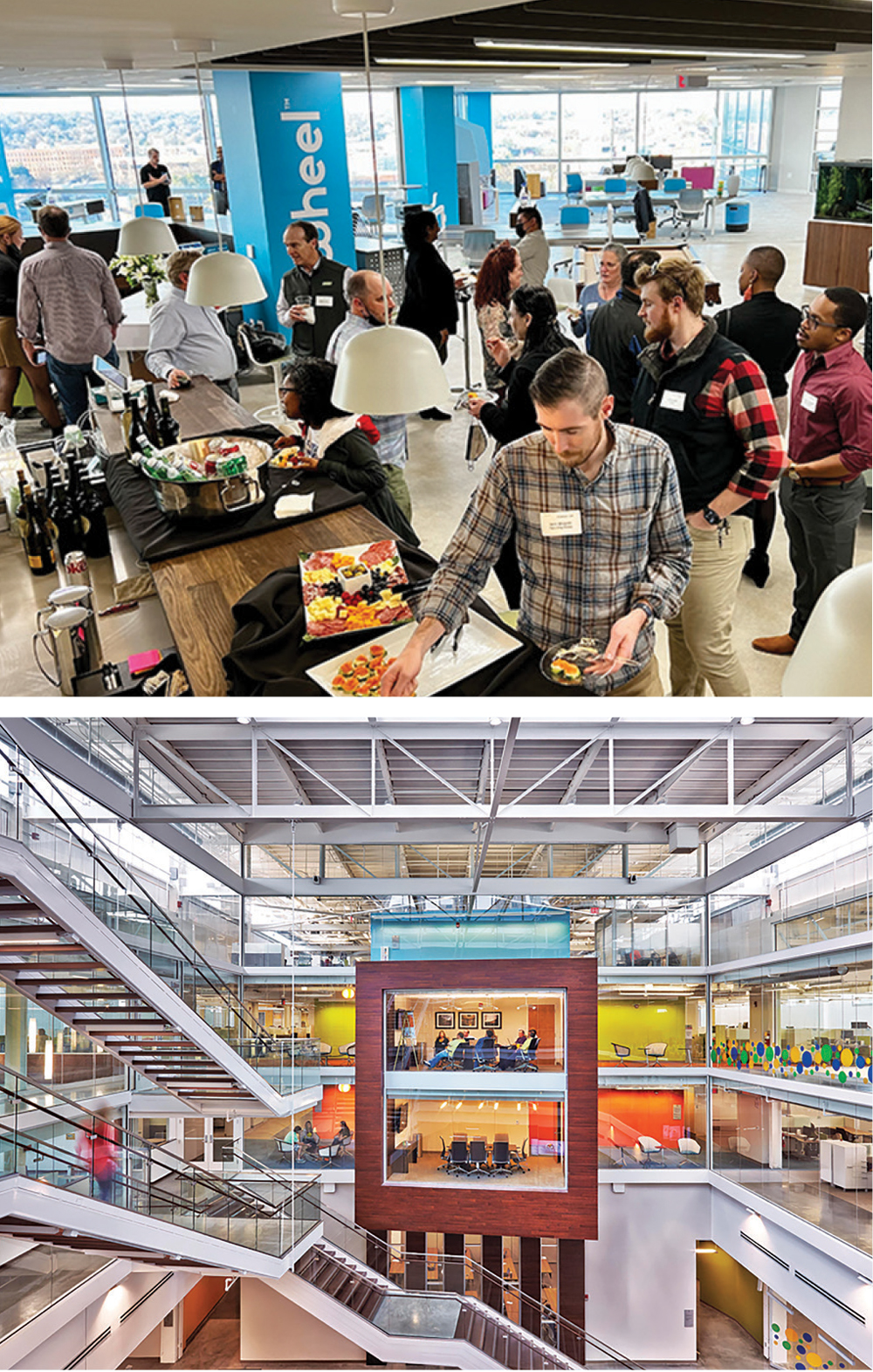

(top) Flywheel Coworking and (bottom) the Innovation Quarter

“The Innovation Quarter, while managed under the auspices of Wake Forest University School of Medicine, exists as a driver within the Winston-Salem and Forsyth County innovation ecosystem,” says James Patterson, the IQ’s director of marketing and communications. “We regularly work with partners from across our region and even the state and globe to make sure we are providing the right kind of environment to help collaboration thrive. For example, our participation as one of the founding members of the Global Institute on Innovation Districts is a signal that we are open to and benefit from collaboration with partners from all over.”

The IQ’s location means people who learn and work there have easy access to arts, entertainment and people elsewhere in downtown. “The Innovation Quarter is the largest technical medical park in the Southeast,” says Nick Gonzalez ,a partner with Linville Team Commercial Real Estate. “The master plan is around 10 million square feet. … We’re really lucky that we have a lot of private and public investment in small business incubators.”

Tenants include:

■ Winston Starts which provides mentors, coaching and resources to entrepreneurs.

■ Flywheel Coworking rents work space and private offices to desks on a weekly and daily basis in its downtown location.

■ Sparq in the IQ’s Bailey Power Plant, offers membership packages for coworking space and conference rooms.

“That power plant was repurposed and has a brewery, a restaurant and a gym. A lot of people live in the apartment next door,” Gonzalez says. “You probably wouldn’t have a development like the power plant if it were in the suburbs.”

A 1.7-mile greenway, Long Beach Trail, runs the length of Innovation Quarter and connects to downtown Winston-Salem, creating a 20-mile loop for pedestrians and cyclists.

HIGH POINT MARKET

For 114 years, the city of High Point has hosted trade shows for the furniture and home interiors industries. An economic study in 2017 showed High Point Market Authority events bring $6.7 billion into the state and contribute to 15,000 jobs for people who attend the

twice-a-year extravaganza.

The market ranks as having the highest economic impact in the state, says Tammy Nagem, president and CEO of the authority.

“It’s because of the way we work with different airports and hotels, and many exhibitors have their corporate offices here in the state,” she says.

“We service about 90 hotels, three airports, two parking lots with about 2,000 spaces and two modes of transportation to move you about downtown, which comes to about 150,000 rides a year out of our transportation system.

“It’s in our DNA,” she says. “We know how to do it.”

The market includes 180 buildings, 11.5 million square-feet of showroom space, buyers, sellers, designers, exhibitors and suppliers. “Our population almost doubles,” during the market period, Nagem says. “You can stand at a stoplight and hear three languages. This isn’t High Point anymore. It’s an international event.”

The authority has been working on four focus areas for the shows:

First: “To really concentrate on new buyer targets. Our goal is to bring those designers, retailers and other buyers in the trade who are looking for product, so our job is to target the right buyers to come to High Point,” Nagem says. The group has been targeting more antique buyers and the luxury sector.

Second: “We want a frictionless guest experience to make sure people are getting a well-rounded experience with the new products, education, networking, providing some entertainment in the evenings such as national act concerts just open to market guests,” she says.

Third: “Technology. We have a technology road map to make sure the buyer and seller connect in a certain way. If you’re at a bus stop, you can look at your app and tell when the bus will be there,” she says. The app has “a lot of good tools and we try to get real time information between the buyer and seller.”

Fourth: “This is nourishing the next generation of home furnishing professionals. That may sound like it’s out of the scope, but the industry is only as healthy as making sure the next generation understands it. We need to make sure there’s diversity and inclusiveness, and make sure the industry is accessible to all.”

HAECO Americas’ hangar, Piedmont Triad International Airport

ACCESS BY AIR AND ROAD

Piedmont Triad International Airport averages 280 takeoffs and landings each day. It’s the home to companies such as FedEx, Honda Aircraft, HAECO Americas, Cessna and Boom Supersonic.

“We’re still a traditional place of transportation, what everyone thinks an airport is, but we also have this mission as part of aerospace employment and we have 8,600 people here in logistics, building and designing airplanes,” says Kevin Baker, PTI’s executive director. “We occupy a very specialized niche in the world of airports because of the land we have [more than 1,000 acres available for economic development]… If Boeing decides they want to make a new airplane, we have the land.”

Greensboro Chamber executive Christensen calls Baker “an incredible airport director because he understands what it takes to get economic development projects and what it takes to keep them for many years to come.”

PTI’s new 180-foot-tall Sen. Kay Hagan Air Traffic Control Tower came on line last November. It has a 15,650-square-foot base that accommodates 10 radar positions and can control airspace within a 60-mile radius, an area that includes 20 general aviation airports. The new tower, which replaces a 90-foot predecessor in use since 1974, cost $58 million.

“[PTI] is into a pretty serious level of preliminary designs of redoing our terminals. We need some updating on the concourses, where you walk out to the planes. Those buildings are 40 years old,” Baker says. “It’s in the early stages of talking with contractors and designers.”

The Triad also benefits from its proximity to Interstates 40 and 85, which bisect the region east to west, and Interstate 77 running north/south. Two new interstates, I-73 and I-74, are completed in most areas and under construction in others. ■